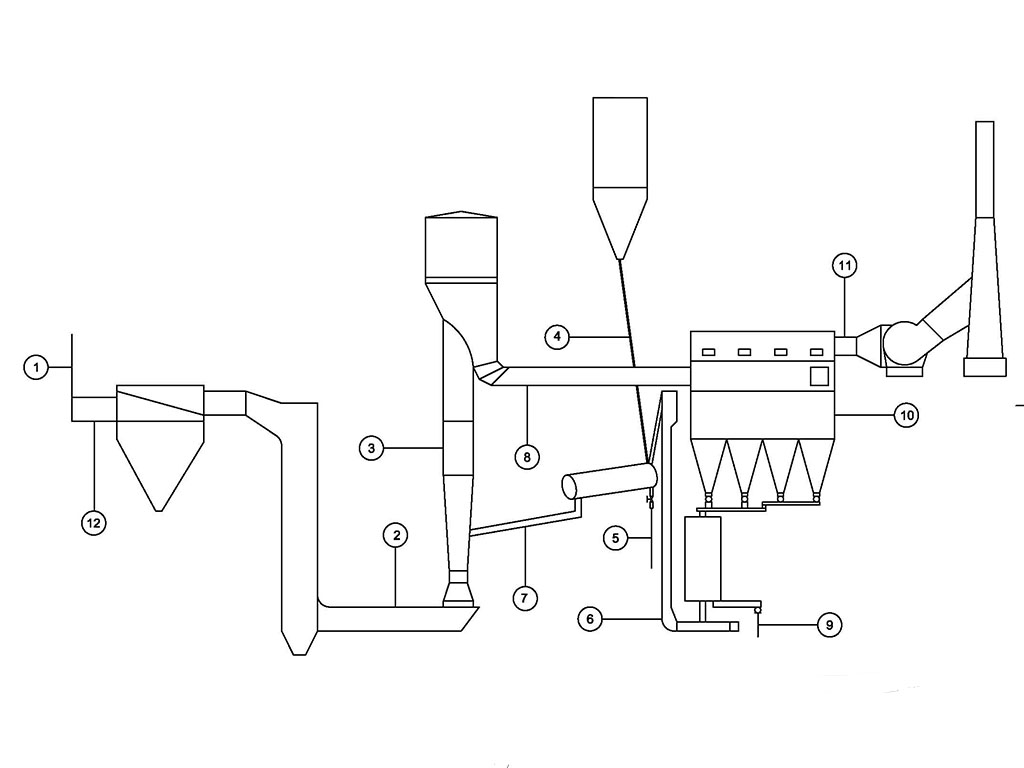

Visy operate a Fluidised Bed Boiler plant at their facility at Gibson Island, Brisbane. The boiler supplies steam for the paper recycling process. The fluid bed combustor is designed for coal as primary fuel but can also burn wood, wood wastes, municipal refuse wastes and mill rejects. Gaseous emissions of SO2 and HCl are controlled by the injection of hydrated lime.

Prior to our involvement problems were experienced with the lime scrubbing system and also limited bag life. Bags became blinded and also suffered chemical degradation.

We generated a model of the combustion conditions in the fluid bed to determine gas volumes and gas constituents. By working with the Visy engineers we were able to refine the analysis and so gain an accurate assesment of the gas conditions through the boiler and into the fabric filter. Heimbach Filtration GmbH carried out laboratory analysis of bags that had been in service and also carried out analysis of the flyash. This allowed us to gain a good understanding of operating conditions and the reasons for the limited bag life that was being achieved.

(We work exclusively with Heimbach Filtration GmbH for the supply of Filter Bags. The Heimbach Group celebrated it's 200 year anniversary in 2011 and currently employs 1600 people globally.)

Heimbach are premium suppliers of quality needle felt. They have particular expertise in surface construction technology. This ensures that less energy is required for pulsing of the bags and reduces migration of particulate into the fabric. Techniques for achieving this include:

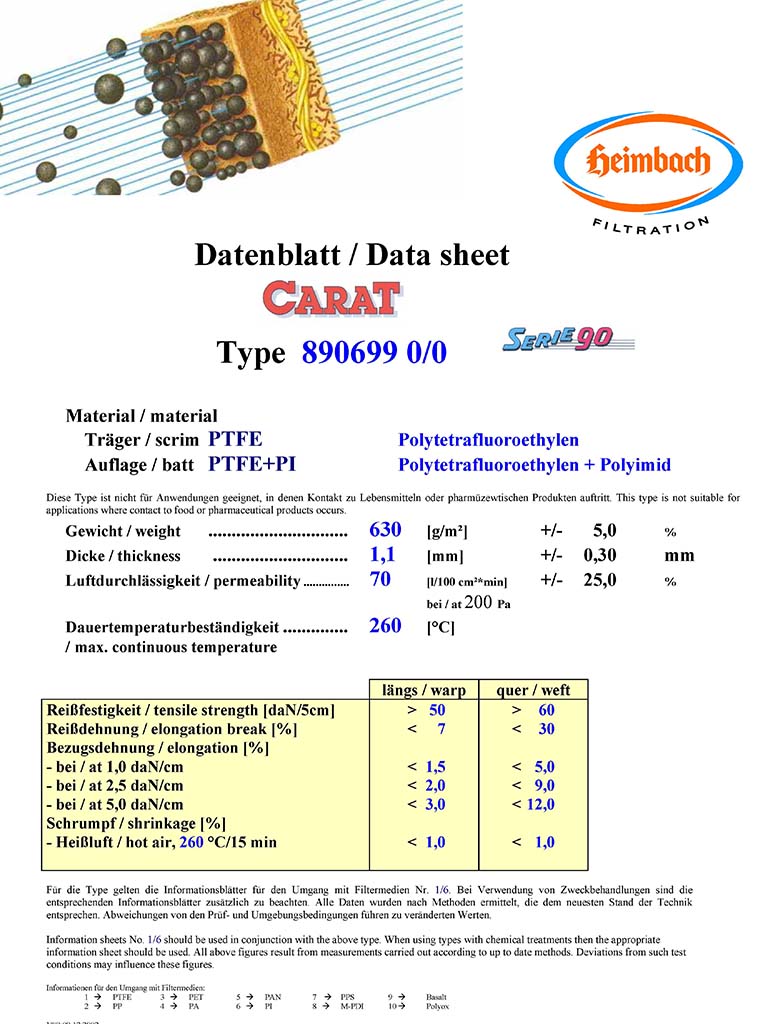

- The Heimbach CARAT construction which is a blend of fine denier and multi lobal fibres needled into the surface to provide additional surface area.

- The Heimbach SERIE 90 sintered PTFE treatment.

Based on the gas analysis and laboratory testing Heimbach made the following recommendations for the Visy Filter bags:

- PTFE as a preferred polymer but as a minimum a PTFE scrim.

- The Heimbach CARAT construction.

- The Heimbach SERIE 90 coating.

To date we have supplied 3 sets of bags with orders placed in October 2001, June 2005 February 2007. Prior to the 2007 order Visy had problems with the economiser which resulted in high back end temperatures. The bags selected were a full PTFE construction Heimbach 890699 0/0 CARAT SERIE 90 (see right) to cope with the higher temperature and to build on the experience of previous bag sets. A bag life exceeding 5 years was achieved of which we are very proud. The photo of the tube sheet taken after extended operation gives an indication of the bag performance.

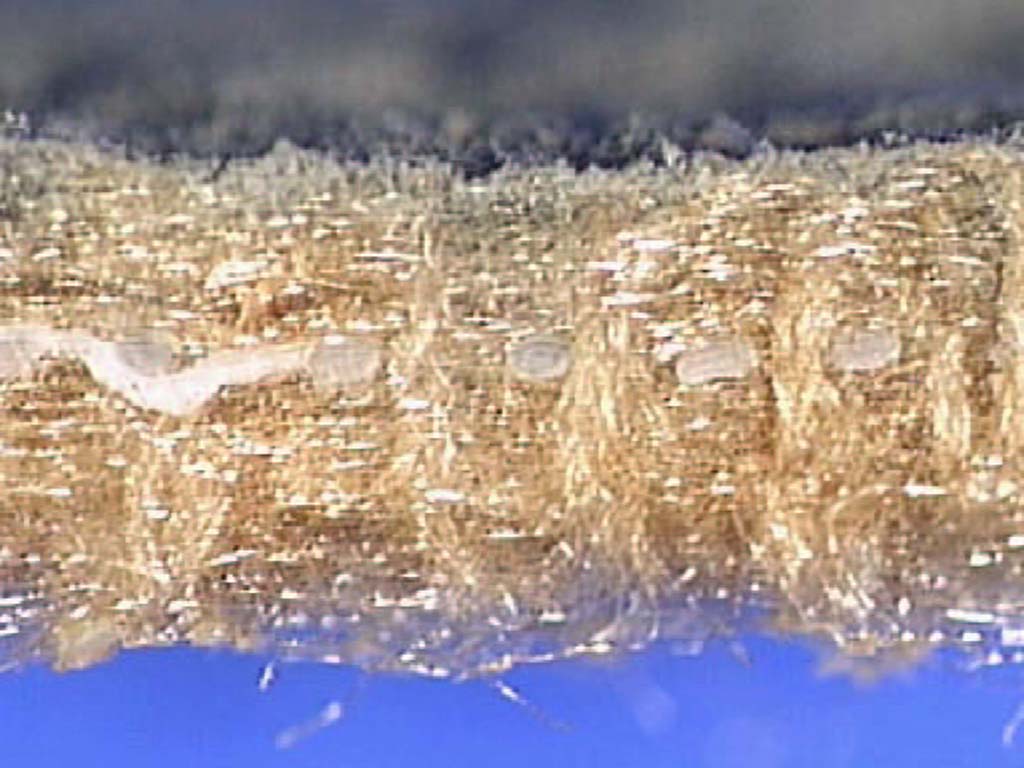

During the operation bags were made available for analysis in the Heimbach laboratory. See the cross section of a bag tested after 18 months of operation (right). The ash was contained at the surface and the needle felt around the scrim is still clear.

This ongoing testing and analysis enabled us to establish the condition of the bags and advise Visy on the next replacement cycle.

Go to TOP: Go to PRODUCTS: Go to ABOUT US: Go HOME

Bag Cross Section

Bag Cross Section